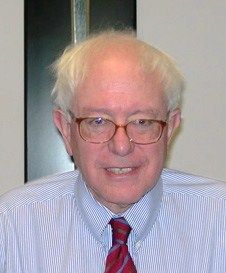

Bernie Sanders on Renewable Energy

Here’s an article by Vermont Senator Bernie Sanders on renewable energy, sustainability, energy policy, climate change, and energy efficiency: items one would think would enter into a discussion between two prospective leaders of the world’s most powerful country – but were conspicuously absent in each of the four debates. He concludes:

Mitt Romney’s energy policy is a relic of the 19th century. We need a 21st century plan. The fate of the planet is at stake.

I really like Sanders’ style. How someone running as an independent, with such distinctly free-thinking viewpoints, gets elected U.S. senator is something of a mystery. Only in Vermont, I suppose.

Need to have nuclear in the mix. Try powering a steel mill or an aluminum smelter with solar panels and wind turbines. Good luck with that! But I guess Sanders is okay with that because he and most greenies would welcome the demise of heavy industry in the US and the well-paying jobs that go with it.

http://www.prosolartec.com/applications.html

It’s the sun that ultimately provided the energy to create the dinosaurs that died to produce your coal those so many years ago……

We are just harnessing it in a different way…one that doesn’t lead to lung disease or worse.

In the grand scheme of things do you really care if your car runs on gas or electricity (regardless of source)? it is a tool designed to get you and your stuff from point a to point b……

Being green doesn’t mean jobs get sent overseas….heavy industry is energy intensive. If I make steel beams from ore it takes allot more energy than if I remelt old car bodies, recycling makes good economic sense…

Reduce, re-use, recycle, repeat…..

so I recycle the glass from my old incandescent bulbs into new glass for my compact flourescents….and I use less energy to do it than it took to make the original bulbs then I have reduced the amount of raw material that came out of the earth, saving it for another use. I have created a product (jobs) from the reclaimed waste of the incandescent bulbs, I used less energy doing it, so now i can use that energy for making something else….like led lights….

the compact flourescents outlast the incandescents and use less energy to run, the LED lights outlast the compact flourescents and take even less energy to run….

this is progress…but the guy who used to replace the incandescents every 6 months is now out of a job because the LED bulbs last for ten years….

Sorry to but in, however, we need heavy industry powered by what ever cheapest form of energy… to power the machines yet to be developed that MUST create renewable energy parts for pennies on the dollar.

There is simply no other way until after the RE base is developed enough to “create itself”.

Consider that it only takes days to turn around oil from both an energy and economic starting point. Unfortunately, it takes years for RE to recoup (for both energy and money).

Recycling is necessary but only as a learning discipline at this time. It won’t magically get RE on the table(don’t recycle until after you have more in the bin than the energy expended to get it to the smelter in the first place!)

Therefore, if we are to make this happen, we had better spend the money to develop machines (that make RE parts AND batteries!), not on stopping oil 🙂

A little research has revealed that powering a steel mill uses between 360 and 475kWh/ton depending.

I found the following paragraph about arc furnaces in Wikipedia which sums it up nicely.

To produce a ton of steel in an electric arc furnace requires approximately 400 kilowatt-hours per short ton or about 440 kWh per metric tonne; the theoretical minimum amount of energy required to melt a tonne of scrap steel is 300 kWh (melting point 1520°C/2768°F). Therefore, the 300-tonne, 300 MVA EAF mentioned above will require approximately 132 MWh of energy to melt the steel, and a “power-on time” (the time that steel is being melted with an arc) of approximately 37 minutes. Electric arc steelmaking is only economical where there is plentiful electricity, with a well-developed electrical grid. In many locations, mills operate during off-peak hours when utilities have surplus power generating capacity.

In the old days facilities like this were situated near hydroelectric plants and they still could be today. Perhaps new facilities like this should be situated near fields of wind turbines in the midwest to take advantage of that power. 200 X 1.5mW should certainly be enough to do the trick and wind in these regions generally lasts more than 37 minutes.

There are ways to do this.