The Tough Realities of Wind and Solar

Frequent commenter Steven Andrews writes:

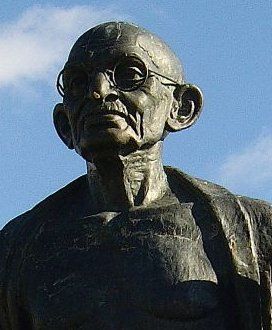

Wind and solar have the best characteristics plus on top of that use no water resources. Why are these systems so under attack by fossil fuel burners? Gandhi said: first they don´t pay attention, then they deny, then… they attack, lastly, we win. Wind and solar don´t consume oil, gas or coal, they don´t leave toxic chemicals, or radioactive materials behind, so they are cheaper and better.

Better, yes — in several senses; cheaper, no.

Having said that, we will get to widespread renewable energy, as you point out with your wonderful reference to Gandhi. The only questions are: a) how much damage we will have done to the ecosystem, and b) who’s going to make a buck in the process.

Big Energy, the people who got obscenely rich in the 20th Century, doesn’t care about the damage, and want to make sure their monopolies continue intact. Are there forces with sufficient power to derail them? We’ll see. According to Victor Hugo, “There is nothing more powerful than an idea whose time has come.” Obviously, I’m one of the many millions trying to make sure that clean energy is indeed, an idea whose time has come.

Does humankind possess the survival instinct and raw guts required to defy Big Energy’s ever-increasing assault on our precious, dying planet? Again, we’ll see. I just got off the phone with my mother – a call in which we both lamented that neither of us will be around in 2100 to see what happens as a result of what I see as the selfish and short-sighted policies of 2012.

If the energy storage problem for solar and wind generation was solved today, the wholesale conversion to those systems would be a no-brainer. But that problem has not been solved and as a result, the intermittent sources like solar and wind will be relegated to about 20-25% of the generation mix. We still need reliable base load and the alternative substitutes for nuclear, coal and natural gas are pretty much limited in availability (at this time). I am speaking of geothermal, hydro and tidal. By the time we could ramp up these alternatives, maybe we will have solved the storage problem.

see my comment below !

You said,”If the energy storage problem for solar and wind generation was solved today, the wholesale conversion to those systems would be a no-brainer. But that problem has not been solved”

The solution is using the GAS network and its tremendous storage already in place and NOT electric which has NO STORAGE.

It would be interesting to determine just how much energy storage would be required to make wind and solar practical. One week? One month? One year or more?

If economical storage were available, it would also make traditional sources of energy more efficient. Research should continue.

You said,”If economical storage were available, it would also make traditional sources of energy more efficient. Research should continue.” Read my post below, the economical storage has been available for about 100 years.

Frank: Storage is now the most important issue to solve, but one week, one month, well, that would be very good, but in a practical sense, just for half a day would be enough to solve most problems, mainly because there is always the cost. Even the cost of storage of any fuel for one week is so great. Oil and the other fossil fuel guys have come to the point of being able to have that capacity because of their ambition of monopolizing their business (that is, keep everybody else out of THEIR business) and their huge pockets, but by having a spread out enough wind and solar devices the levelized production would be good enough. There is always the point where investment and return must have an equilibrium.

…”by having a spread out enough wind and solar devices the levelized production would be good enough. ”

good enough for what?

The peaks and valleys can be leveled somewhat by having a good distribution network that can transfer power from one region to another to balance the load and the supply.

But, the minute leveling that needs to be done to keep 60Hz on the line and a steady e.m.f. requires a base load of demand generation that can make up for imbalances that are beyond the capability of the fluctuating solar and wind output.

A good argument for high voltage DC transmission.

But note that depending on long distance power transmission to make renewables reliable introduces a new risk, i.e., grid failure.

If we can assume that the grid is already there but just needs a few more interconnections at high demand points, the distributed sourcing of wind and solar will just increase the reliability of the grid. The existence of the grid is a given for any modern distribution scheme. The alternative would be stand alone generation in everyone’s backyard. I don’t think that would have much reliability on a large scale.

Stand alone solar and wind projects typically have 4-5 days energy storage.

Business/industry which operate during the day when the sun shines need much less. Some grid connected facilities receive power cost benefits from solar lowering their peak demand.

You have not been listening to me ! I feel like a voice shouting in the wilderness. This world has TWO major distribution networks. Electricity is only one. The other is supported by a tremendous network of storage tanks, pipelines, and metered smaller pipelines to individual homes, and to industry, including electrical power generating plants. That second Utility is Natural Gas ! Someone needs to make the Gas companies an offer, a gas well costs $4,000,000 to drill and 25 years to pay off. The same amount of energy from solar or wind is a much smaller investment. Electricity produced by solar or wind can be easily used to break water down into Hydrogen which can be compressed and fed into Natural Gas Pipelines. (Natural Gas is a mix of Hydrogen and Methane gases, mixing in additional hydrogen still allows the gas to be used without major changes in industrial processes and in homes for heating, and cooking. Select a rural location near a pipeline and build solar or wind (or both) installations then use the electricity to make Hydrogen and pump it into the pipeline with a compressor. The huge storage capacity of the gas distribution system eliminates the problem of intermittent output by solar and wins generation. Think outside the box! Electric generating plants and their “Peaking units” burn gas! We can get away from a large percentage of coal consumption. The gas pipeline and storage tank system is in place build the solar and wind generators and make Hydrogen to add to the Natural Gas mixture.

hydrogen production by electrolysis is one way to store solar energy but there are thermal losses and hydrogen storage is not simple. Metal embrittlement and leakage from micropores is problematic due to the small molecular size. Hydrogen leaks will spontaneously combust. Gasoline is quite docile compared to hydrogen.

The problems with hydrogen make it uneconomic at this point in time.

Natural gas has very little if any hydrogen. The components in addition to methane are mainly the higher order alkanes. The composition varies. Wet gas from fracking has quite a few higher molecular weight components.

Natural gas today is way less expensive to obtain and use as a fuel compared to the cost of hydrogen per thermal unit no matter how you make the hydrogen.

Not only that, but converting water into H2 is a very inefficient process.

Well then Frank forget ever having an effective fuel cell system because they convert natural gas to hydrogen at a 50% loss, or use the electric power for breaking water down into Hydrogen and Oxygen this process is 95% efficient and I certainly would not consider that 95% as Inefficient.

Dennis,

Fuel systems that use natural gas for fuel cannot destroy the carbon in the CH4; it has to go some place and would most likely be emitted as CO2.

Although there may be developments of which I am unaware, electrolyzing water into H2 and O2 has always been inefficient.

Thinking outside the box seems to be a hard thing for many to do.

A system such as the one you described is being installed in Germany. Hydrogenics is supplying the electrolyzer, which generates hydrogen from wind power and feeds it into existing natural gas lines. It’s not rocket science. Neither is it rocket science to deal with the hydrogen directly. We have been using hydrogen for more than 150 years. The fossil fuel industry handles it routinely. One gas supplier (Praxair) has some 310 miles of hydrogen pipeline in the Gulf area, complete with a huge underground cavern storage chamber, which delivers hydrogen to refineries for desulfurization of diesel fuels. This is routine, and obviously not prohibitively expensive. In fact, most natural gas lines can as easily handle hydrogen.

As for the other comments on your entry:

Electrolysis efficiency ranges from 65% to better than 85%, depending on size and type of electrolyzer. This is far better than the conversion efficiency of any fossil fuel plant. At point of use, you have a choice whether to convert back to electricity, which can be done efficiently with fuel cells, or used as a fuel (as, for example, in a fuel cell electric vehicle). If mixed with natural gas, it can be used directly in solid oxide fuel cells (for example, the “BloomBox”; ITT is installing large numbers of these to supply their energy needs).

Metal embrittlement and micropore leakages occur only at elevated temperatures, which are not needed for hydrogen storage. Hydrogen self combustion heppens only at much higher temperatures than would be encountered in a hydrogen storage system. Unless leaked into a confined space, hydrogen will disperse into a noncombustible concentration level. And no, gasoline is NOT more “docile” than hydrogen; gasoline has 22 times more explosive energy than hydrogen (44.2 on the EEV scale as opposed to 2.02 for hydrogen), requires only 1/16 as much air for combustion, and the vapors tend to hang around over the spill, waiting for a chance to ignite. People have been killed or seriously injured as a result of smoking while refueling their vehicles, or attempting to weld a supposedly empty fuel tank (which still had vapor in it).

Natural gas is the principle source of hydrogen for the fossil fuel industry (by steam distillation); how could that be if natural gas has “little or no hydrogen in it”?

Methane is basically NH4, and any hydrocarbon, by definition, contains hydrogen. Methane itself can be obtained from other sources, including plant residue and animal waste, and is a byproduct of waste disposal and water treatment plants; both methane and hydrogen are also byproducts of many industrial processes. We need to be making use of these energy sources as well.

Just as importantly, we need to be shifting away from large centralized power generation systems wherever appropriate (right down to home-sized combined heating and power units, as is being done in Japan); centralized plants have high energy overhead and high transmission costs as well as high transmission losses.

Here’s a poser for you: how to provide power to the northern communities in Canada. Right now, gasoline is sent to those communities for local generation, as it is prohibitively expensive and inneficient to build electric transmission lines to such remote places. However, it is also expensive to transport gasoline to such places, as ice roads have to be maintained and travelled in the wintertime, and a year’s supply has to be delivered in a short season (which is getting shorter each year as the Arctic warms up). If the supply runs out prematurely, gasoline has to be delivered by air, at even higher cost (if you think gasoline is expensive at $5.00/gallon, try $80.00/gallon!).

These communities are adding wind power to their systems, but still rely on gasoline as base power. We now know that the Arctic contains stores of natural gas, which they could be using, with very little development effort. What is the fossil fuel industry’s proposed solution to this? To construct pipelines to bring all the natural gas south, and to business as usual concerning the gasoline supply.

A local Ottawa company which specializes in high-reliability battery systems is working on an alternate solution involving additional wind power with battery storage, to alleviate the fossil fuel requirement entirely. Will it work? I hope so.

By the way, these communities do not pay $80.00/gallon; the gasoline is subsidized by our southern communities through the provincial governments. Try running that deal by your Tea Party friends (most of us don’t complain, and many of us aren’t even aware of it).

…Natural gas is the principle source of hydrogen for the fossil fuel industry (by steam distillation); how could that be if natural gas has “little or no hydrogen in it”?

Methane is basically NH4, and any hydrocarbon, by definition, contains hydrogen….

Natural gas has little or no UNCOMBINED FREE hdyrogen. This was implied.

Hydrogen in natural gas is combined with carbon and the nature of hydrogen is no longer displayed. Chemistry tends to alter the displayed characteristics of elements when they are combined. Transmission of hydrogen as an additive to natural gas in a pipeline may very well be possible as long as the concentration is low. A special, much more expensive pipeline with a higher degree of inspection for micropore leaks would be needed for transmission of pure hydrogen.

The proposed concentration of hydrogen in the natural gas pipeline is 10% maximum. This is not expected to create a problem.

I agree with you all that the storage is the biggest problem.

I think it will take a few years until we find a final solution for the storage of large amounts of energy produced from renewables.

It may be that a way will never be found to store large amounts of energy economically. Surely it is reasonable to question the logic of depending on something that may never occur.

Doty Windfuels has a great storage solution based on excess wind power.

Externalized costs of fossils energy are not in the equation and should be. Molten salt and pumped hydro are both proven viable for storage of CSP harvests.

Although it’s true that molten salt and pumped hydro can be used for energy storage, their practicality is limited.

Pumped hydro is dependent on local geography. It requires two large nearby reservoirs at greatly differing altitudes and those are available only at limited locations. It has been successfully used for decades where geography permits.

Molten salt require a huge insulated tank to store the molten salt and that is expensive if large amounts of energy are to be stored. It is useful only for solar systems.

When we discuss the costs of wind and solar and other renewables, are we including external costs from those energy sources?

It’s an apples-to-oranges cost comparison to fossils, but are “we” being up-front about our costs (to our detriment) while the fossil guys are obviously (to us) not?

Probably not.

Wind and solar power require far more concrete and steel than fossil fuel and nuclear plants. Wind power requires approximately 10 times as much steel and 30 times as much concrete. I don’t have the figures for solar power, but it also requires more concrete and steel.

Making the concrete and steel emits CO2. Of course, once installed, wind and solar do not continue to emit that much CO2 since the amount is reduced only to what is required for maintenance which is much less than what is emitted by fossil fueled systems.

Solar construction costs might be hard to pin down as so much depends on the type of installation. For example, a rooftop installation would require no concrete and probably negligible steel, as the structure would likely be made of aluminum to minimize roof loading. The amount of aluminum used could be minimal unless the roof slope is inappropriate and requires additional structure to lift the panels. Ground installations would more likely be steel, and I expect concentrated solar systems would require substantially more concrete and steel than flat panel systems. As for the cells themselves, thin film cells consist almost entirely of the glass substrate, and the amount of silicon required in silicon cells is dropping substantially with improved manufacturing processes.

“The amount of aluminum used could be minimal unless the roof slope is inappropriate and requires additional structure to lift the panels.”

Generally, when buildings were constructed, solar panels were not taken into consideration. Therefore brackets to orient the panels efficiently would often be required.

Another consideration is the composition of the roof. Many roofs have to be replaced periodically which is significantly more complicated if there are solar panels on it. However, if the roof is metal (and metal roofs are becoming more common), the roof may have a life exceeding 50 years.

Usually, but not always, concentrated solar systems generate steam to drive turbines and generators. I’ve never heard of putting them on roofs.

The principal problem with using solar power for electricity is that it is an intermittent source of power, a problem for which no practical and economical solution has been found that is usable on a large scale. Although solar power is quite useful in niche situations, I cannot see its being used as a major source of power for large countries. Nuclear power, using a better nuclear technology than what is now being used, seems more realistic. In any case, it seems unreasonable to put practically all emphasis on renewables without having a “plan B.”

Check out the following web site for a potentially much better nuclear technology: http://www.youtube.com/watch?v=lG1YjDdI_c8

Having worked in refineries and nuclear plants, and then comparing them to utility scale solar and wind installations, I cannot imagine where you are getting your information. The former are massively more steel and concrete intensive (not to mention other complexities) than the latter.

Docility has more than one factor.

Although on a per unit weight and per unit volume basis, gasoline has more explosive power than H2, and that factor could be used to state that it is less docile than H2, there are over-riding considerations.

Gasoline is not stored under high pressure whereas H2 has to be stored under extremely high pressures to get its volume down to something practical. H2 is also more easily ignited. It’s upper and lower explosive limits are much farther apart meaning that when mixed with air, it is explosive over a much wider range. It also reacts with metals to make them more brittle. Because of its much smaller molecular size, and because of the extremely high pressures under which it must be stored, leaks are much more difficult to prevent. It’s one strong point is that, because it is lighter than air, if a leak occurs, the leaked H2 will rise and probably escape instead of accumulating, like gasoline vapor, in a low lying area.

With everything taken into consideration, gasoline is much more docile than H2.

Honda uses 5,000 psi in the Clarity; GM, Daimler, Toyota, and Hyundai use 10,000psi. These pressures can hardly be described as “extremely high”, given that pressures of 10,000psi and above are used in fracking operations, and pressures ranging from 20,000psi to 34,000psi are used in the fuel rails of diesel engines. Higher pressures are used in many industrial operations; it’s routine. And, by the way, pressures upwards of 5,000psi can exist in the accumulators of ABS braking systems during operation.

It is important to remember that the high pressures exist only in the storage tank; as the gas exits the tank, a prssure reduction valve located in the tank at its outlet drops the pressure- typically to somewhere in the range of 5psi to 50psi (my model fuel cell train operates at 6psi).

Again, embrittlement happens under high temperatures which are not present in hydrogen storage systems, or when inappropriate materials (for example, iron and certain nickle alloys) are used. The most common gas-handling materials (brass, copper, austenitic stainless steels, nitrile seals, silicone and teflon tubing, etc.) have no problem dealing with hydrogen.

There are other ways of increasing storage density than high (as opposed to “extremely high”) pressures. One is liquifaction (appropriate for certain applications; NASA deals with it routinely); another is the use of a hydride. This latter method is used in my hydrogen fuel cell train; it operates at 250psi. I refuel using an industrial pressurized tank filled to an initial pressure of 1800psi.

For both gasoline and hydrogen, ignitability varies widely with concentration. It is true that at the stoichiometric mixture (the point where ignition energy is lowest) hydrogen requires less energy for ignition than gasoline; however, this point occurs at about 35% fuel in air for hydrogen; for gasoline, it is around 4%.

I have used both gasoline and hydrogen; I most definitely prefer the hydrogen.

…Again, embrittlement happens under high temperatures which are not present in hydrogen storage systems, or when inappropriate materials (for example, iron and certain nickle alloys) are used. The most common gas-handling materials (brass, copper, austenitic stainless steels, nitrile seals, silicone and teflon tubing, etc.) have no problem dealing with hydrogen….

These materials that you would use for a hydrogen pipeline, just how expensive do you think it would be to make hundreds of miles of this stuff? Welded iron pipe is cheap compared to brass, copper, and stainless but iron and hydrogen have issues.

Most pipelines are made out of mild steels which ARE compatible with hydrogen- I inadvertantly left this material off the list.

…Honda uses 5,000 psi in the Clarity; GM, Daimler, Toyota, and Hyundai use 10,000psi. These pressures can hardly be described as “extremely high”, given that pressures of 10,000psi and above are used in fracking operations, and pressures ranging from 20,000psi to 34,000psi are used in the fuel rails of diesel engines. Higher pressures are used in many industrial operations; it’s routine. And, by the way, pressures upwards of 5,000psi can exist in the accumulators of ABS braking systems during operation. It is important to remember that the high pressures exist only in the storage tank; as the gas exits the tank…

But, because those high pressures are needed for very short transmission distances, it is doable economically. You can use extremely rigid manufacturing precision if you only need a few feet of leak-proof tubing. Scale that quality of production up to miles and it becomes a deal breaker.

Fracking high pressures can be obtained relatively cheaply because the pressure in being transmitted underground where the application requires “leakage” into the reservoir to get the propant into place.

Praxair has scaled it up to 310 miles for the fossil fuel industry.

8.2: Hydrogen Distribution and Storage

By David A. J. Rand (eds)

From Clean Energy

8.2 Hydrogen Distribution and Storage

Gaseous Hydrogen

In principle, hydrogen is an ideal vector for the transmission and storage of energy. One might imagine, in the post-fossil-fuel age, huge solar collectors and electrolysis plants located over large areas of desert. It would then be necessary to convey the hydrogen to market. The most obvious means would appear to be via pipeline. Indeed, as long ago as 1938, conventional mild-steel pipelines were installed in the Ruhr district of Germany to convey hydrogen between refineries and chemical works. The initial system was about 24 km in length and fed two plants. Since then, the grid has been expanded to a 210-km network that links four producers of the gas and thirteen users. It even crosses the Rhine in two places. The pipes are wrapped in bitumen and plastic, have diameters of 15 30 cm, and operate at pressures up to 1.6 MPa (16 atm.). Remarkably, no major accidents have arisen from escaping hydrogen or potentially explosive hydrogen-air mixtures. There is also a 170-km system in Northern France and a total of some 1500 km in Europe as a whole. North America has at least 700 km, and other smaller networks are in use in South Korea and Thailand. Clearly, the technology of transmitting pressurized hydrogen safely over considerable distances has been demonstrated and used commercially to supply gas for chemical processes.

Hydrogen as an energy vector is a rather different proposition since the distances involved are likely to be much greater and…

ref last paragraph:

A little thinking outside the box is required here.

Why should any hydrogen transmission distances be greater than the practical ones sited in the first paragraph? Given the desirability of distributed energy generation and storage, why would we have to connect every hydrogen storage system with every other, regardless of distance? Why must we always think in terms of megasystems?

In fact, why would we limit generation and storage systems to hydrogen only? We could certainly supplement the system with any of the other storage systems mentioned here, where appropriate. Consider the goals, and find the best way to get there.

My main point is that hydrogen should be seriously considered among the options available.

“Honda uses 5,000 psi in the Clarity; GM, Daimler, Toyota, and Hyundai use 10,000psi. These pressures can hardly be described as “extremely high”, given that pressures of 10,000psi and above are used in fracking operations, and pressures ranging from 20,000psi to 34,000psi are used in the fuel rails of diesel engines.”

True, but that is exceedingly misleading.

I am quite familiar with Diesel injection systems. The fuel rails consist of fairly small tubing. It is easy to handle high pressures with small tubing. Tanks large enough to store sufficient fuel are a different matter. As for fracking operations, the pipes are underground where bursting would be of limited consequence. Moreover, they contain a LIQUID, not a gas.

Because liquids are relatively incompressible, very little happens when a pipe containing a liquid bursts. On the other hand, when a tank containing a gas bursts, the gas quickly expands thereby creating a much more dangerous situation. Explosions of pressure vessels containing gasses are among the most serious industrial accidents which is why many jurisdictions require periodic inspections of such pressure vessels. Commonly periodic hydraulic pressure testing is required since if the vessel bursts when it is completely filled with a liquid, the result is much less dangerous.

It is true that H2 can be stored in tanks; it has been done for decades. But having large enough tanks in cars running on H2 to permit driving long distances is a problem. Storing enough H2 to store energy for a power grid would be even more challenging.

A few years ago I heard a lecture by a chemist who said in his opinion the best way to store hydrogen was to combine it with CO2 in the air to make alcohol. Then it is easily stored for long periods of time. When you eventually burn the alcohol you are not creating any more pollution than there was at the beginning of the process. Does that make sense to anybody? Thanks.

I hadn’t previously head of combining H2 with atmospheric CO2 to make alcohol, so I cannot comment on it. Perhaps research should be done to determine its practicality. It does seem strange that the concept has received little publicity, but that does not mean that it would be impractical.

What IS currently being worked on is using renewably generated H2 with CO2 to make a synthetic gasoline which can be used in any gasoline-powered automobile. The gas-powered cars made today are going to be on the road for an average of up to 20 years, so such a fuel might be useful.

Do you have a link to any news or journal article that references this H2/CO2 fuel cocktail?

It sounds like the energy inputs would approximate the fuel output yield. And, the CO2 would end right back in the atmosphere when its initial removal took great pains to accomplish.

I believe Craig has the company in his portfolio -he should be able to supply the info.

Capturing the CO2 at its source would be more practical than removing it from the atmosphere. This is preferable to letting it escape and digging more CO2-producing fuel out of the ground, to make more CO2 to also escape later.

Hopefully, of course, we will eventually stop producing gasoline-powered vehicles. But in the meantime-

Yes, it’s Doty WindFuels: http://2greenenergy.com/doty-windfuels-breakthrough-in-synthetic-fuels-provides-break-taking-promise-fist-clenching-frustration/31403/.

Capturing the CO2 at its source would be more practical ..

It should be but the poster child for this process was cancelled in Illinois by Obamanomics. The coal mine-mouth generation of electricity with carbon capture was put on indefinite hold. Even with massive government subsidies, the reversal of massive positive entropy change is generally a losing proposition. It just doesn’t scale up from a bench top experiment.

Yes, it’s called “carbon neutrality.” Btw, alcohols are just one form of hydrocarbon that are produced. The process is called “Fischer-Tropsch” – http://en.wikipedia.org/wiki/Fischer%E2%80%93Tropsch_process.

????

http://en.wikipedia.org/wiki/Fischer%E2%80%93Tropsch_process

Carbon monoxide not carbon dioxide is involved in the Fischer Tropsch reaction.

There is a big difference here. Carbon dioxide does not have the favorable entropy drive to make this reaction go spontaneously. Even with a little help from our friends, the activation energy hill is a tough sell. I will still put my money on horizontal fracking to get my hydrocarbons.

Sorry. You’re right, of course.

The importance of the storage problem may be overplayed here. If the grid is big enough intermittency is much less of an issue.

On the demand side it is chaotic, no one controls when consumers turn on or off light switches or air conditioning, but aggregated demand is reasonably predictable and has been well-managed for more than 100 years now. The same predictability is possible on the supply side.

At the same time, I must agree that a price on pollution is a Must. At present there is a classic market failure. Neither the buyer nor the seller of coal power wants to pay for the damage the pollution causes, so both of them simply ignore it.

“The importance of the storage problem may be overplayed here”. I would say is being overplayed, particularly for solar, which will not provide more than several percent of the US electricity demand until after 2020.

Meanwhile, residential and commercial air conditioning (AC) demand represents over 10% of the annual US electricity consumption. The peak load on the grid occurs during the day in the summer, when solar radiation is quite strong.

The building structure with its thermal mass should limit temperature swings. Some thermal storage can also be provided such as is used now to take advantage of low off-peak nightly rates to make ice for use in 12 or so hours later.

compressed air can store the renewable energies quite nicely and in a distributed manner, lessening distrubution losses, grid expense, grid fragility and local vulnerability to distant events.

nuclear as uses less steel & concrete than wind & solar? give me a break, please! The wind blows & the sun shines-for free. And leaves behind no persistently hazardous materials that must be stored in steel & concrete till the end of time.

IMO trees still do a superior job in storing wind & solar energy.

The WaveFarm Invention is a altenate energy technology that offers a way for oil, gas, and coal industry to profit by helping to reverse the damage to our environment. No it’s not wave power, but something much more powerful as a source of energy and much vaster as a energy resource . It’s something caused by the surface waves: Hydrostatic Pressure Differential power (HPD power). This invention is a simple, easy, and ergo likely less expensive(In terms of the building cost per a KWH of generating capacity) way to tap into that vast but little known energy resource. Therefore it is likely profitable to build power plants using this concept: deals can be structured for quick ROI, debt servicing takes less out of the gross, no fuel costs, hardly any down time (The waves that cause usable HPD power roll all night and day practically) No, I have’nt had independent testing done to verify my test results. Also, sea trials are needed before anyone can be sure of the building costs to KWH generating capacity, but I certainly hope to find some one who sees the potential of this concept, and who will help me get such testing done. I’ve exhuasted my resources so I hoping some one out there gets the picture and will help me get this in a university lab. I suspect it would only take less than $3-4K dollars and some good contacts at such a university to accomplish this. Anybody out there got any suggestions? A video of the invention is avaiable on Youtube at the following LINK .http://www.youtube.com/watch?v=bEtcM5ibbWg

Base loads can be supplied on demand by recirculating used hydro water back to the resevoir by off peak availability of wind & solar. Already in use by some countries.

A new world for 2100 starts to became real today. The creation of a renewable energies based model needs a set of initiatives and motivated people (like you) today to make real solutions in the future. We create the future acting in the present

That’s exactly right, Vicente. Thanks.

I work for a company that is on the verge of receiving the final license for a 1000mw closed loop pumped storage project. After reading the preceding comments a few things stand out that are not considered or at least mentioned #1 Water availability for hydrogen production and more important the regulatory requirements to either bury pipelines or build transmission; I have been involved in both and the process is both expensive and time consuming. If someone thinks they have found the answer to energy storage or distribution at a reasonable cost they haven’t been involved in the permitting or licensing process our government requires and they haven’t talked to the vast community of NIMBY’s that will fight any and all pipeline or transmission effort.

We have located and plem. permitted numerous closed loop pump storage sites and are working on licensing them but the process is long and the environmental /recreational nexus must be overcome before reality can be attained. However the team is doing just that and doing it well. Remember ANY successful business that runs a supply line for their product must have storage or they face shortages and customer loss – energy is no different and storage is the answer. I just can’t explain why the wind industry has been in denial over this fact. Reality is on its way.

Please see: http://2greenenergy.com/renewables-and-energy-storage/32659/.

Here is a link to a web page that compares the amount of concrete and steel required for nuclear, wind, and coal plants; the information is near the top of the page and there is a link to a clearer display:

http://nextbigfuture.com/2008/07/per-peterson-information-on-steel-and.html

As can be seen, wind generators require far more concrete and steel than either coal or nuclear systems.

The first commenter said,”If the energy storage problem for solar and wind generation was solved today, the wholesale conversion to those systems would be a no-brainer. But that problem has not been solved” and then provided one solution.

He said; “The solution is using the GAS network and its tremendous storage already in place and NOT electric which has NO STORAGE” but the fact is that gas can be produced and stored and used on demand with the new power delivery system my firm technology offers. The AAEC technology is also designed to use trash which is already being generated and stored in vast amounts all around the nation.

I am the developer of fuels conversion technology that may be of interest to alternative energy and renewable energy firms that are looking for the novel new conversion tech that could serve as core technology for new generation of both power and biofuels in new bioenergy plants that can be distributed among the feedstock supply resources at county scale and I am seeking investors and a strategic alliance.

Contact

Les Blevins

Advanced Alternative Energy

Lawrence, KS

LBlevins@aaecorp.com

785-842-1943