From Guest Blogger Kara Masterson: Green and Growing–How Modern Manufacturers Are Making Strides Toward Sustainability

While there was a time when manufacturers in America had a reputation (sometimes deservedly) as “despoilers of the natural environment”, that has changed markedly in the last several decades. As it becomes more and more apparent through climate change, global warming, and other environmental warnings that not only is it not nice to fool Mother Nature, she doesn’t care for abuse or overuse. Major manufacturers are taking heed. For example, General Electric, the Ford Motor Company, Coca-Cola, and Nike have reported planned changes or have already implemented programs designed to improve both employee culture and actual production in terms of less waste.

Less fossil fuel use, less water wasting, and more sustainable designs are among the changes. But some of these ideas are still in the idea stage, or will take years to fully see positive environmental results. Fortunately, some of their peers are already ahead in this category. Their efforts show how both sustainability and effective manufacturing growth are possible. Below are some examples.

Dell

Not only does the computer giant’s packaging now consist of largely recyclable materials, its products are now far more energy-efficient, and much easier themselves to recycle. Dell also was able to make the very first recycled computer. Some of their packaging is now made out of wheat straw and uses 40% less energy.

Starbucks Coffee

The global café and beverage giant has had a sustainability program in place for nearly two decades that includes environmentally friendly farming programs in Third World countries, ethical trading practices for their products, and environmentally friendly practices in Starbucks café stores themselves. These measures include environmentally friendly packaging and beverage containers, and the types of furniture used in such stores, and their placement within them.

Adobe

The software development company has pledged to reduce its carbon footprint by 75% over a fifteen year period in the 21st century. Currently, it has replaced many electrically operated components with solar power and hydrogen-celled ones. It has also replaced many of its data “cooling centers” with more energy efficient ones.

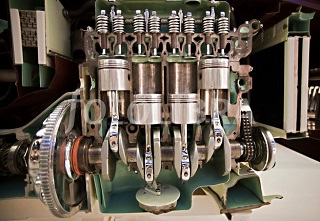

The Metal Fabrication Industry

Many metal fabrication factories are going green across the world and are starting to use much greener equipment and solutions. Some of these types of businesses can even get help from agencies such as the “Green Supplier’s Network” to get help with figuring out how to be more environmentally friendly. This new wave green is really impacting a lot of companies, such as Ceramic Technology Inc, and helping them Improve their business sustainability. That way they can save money while saving the environment.

While emissions and “footprints” in manufacturing can’t be completely eradicated, study results over the last decade have shown that efforts by these and other companies show a positive partnership between manufacturing and sustainability, moving forward.