How Feasible Is This Energy Storage Device?

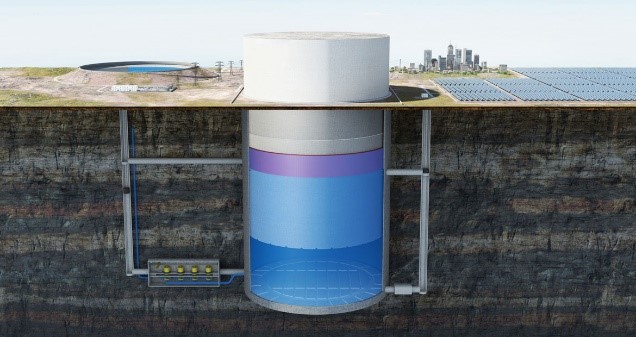

Apparently, it’s a proposed solution to the problem pumped hydro faces where there are no natural changes in elevation. Obviously, there is nothing theoretically impossible here, but how feasible is it to build something where the force against the “piston rings” is that huge?

Also, it pains me when people who wish to be taken seriously say, “It uses gravitation power.” No, it uses the potential energy created from the work done to move a mass against the force of gravity.

Interesting concept. It does look like it would be quite cheap to build, and it should have a reasonably long cycle life and fast load response…

The problem would be the cycle efficiency. To lift the massive rock cylinder with water you obviously would need sufficient water pressure to accommodate that lift, which means you would need compressors. Those compressors would generate heat, which isn’t a surprise, but that heat would be largely exhausted. You could use some recuperative cooling to pre-heat the water before compression, but you’d still see considerable thermal loss, and then you’d have a large well of compressed hot water that would slowly cool via conduction. All of the heat that is produced and not maintained in the compressed water before expansion would be lost efficiency.

The higher the pressure, the greater the amount of heat lost to compress the water (a high-compression hydrocarbon fluid might be a better choice), so as the energy storage density increases (and the cost/MWh of energy storage decreases), the efficiency will decrease.

Note this isn’t a dismissal… the concept is interesting. I would need to see cost estimates and think about it… But this is my initial reaction seeing it for the first time.

One way to solve that issue is by raising it with an electromagnet. Then the water would automatically flow under it since water flows from places of high pressure to low pressure, which could also spin the turbines.

It’s also worth pointing out that any of the fluid that seeps around the floating rock will also, obviously, represent efficiency loss.

We think of a piston/cylinder seal as something that is easy to accomplish, because we do it by the billions in the auto industry. But it is NOT easy to scale up to the scale that we are discussing here.

A cylinder and piston for a car engine can be done accurately on a machines and tools that have a well-trued spindle. Even then you use oil and grease to help seal the walls

But if you’re talking about a disk that is 20 meters diameter, you aren’t grinding the edges by turning it down on a lathe. It will be ground and polished by machinery that encircles and travels circularly around the center, while the bore of the hole would be bored out and then lined and polished by machinery that is much smaller than the radius of the hole. Getting the surfaces of these two projects to line up tightly enough that very high pressure water does not seep through? It is not a trivial construction process.

Again, not a dismissal.. just some thoughts.

Yes. As usual, you know more about it than I, but this exactly what I thought.

Craig,

The problem confronting such devices being practical, is fairly obvious. Setting aside the cost of construction, (although the engineering is simple) the problem remains as to why would anyone bother ?

Let’s say there was an abundant free surplus power source from Wind or Solar or even hydro, the energy stored, and then recovered, wouldn’t be competitive with a conventional fuel such as natural gas etc.

The cost of construction on a scale to compensate for a drop in dam levels caused by drought would be impossibly expensive, and if built on a small scale the output would be uneconomic.

It would be far cheaper to simply build a water tower. most cities are blessed with water towers, and the economics of using gravity to generate electricity by harnessing the potential energy water from a tower being forced by gravity through a diminishing diameter, has been available for nearly 150 years.

Large scale thermal storage is also fairly cost effective – slush ice storage to provide air conditioning / refrigeration, and big tanks of hot water (Both simultaneously produced off the same heat pump operated as a “dump load” whenever electricity is cheap or would otherwise have to be curtailed.

The bigger the better – billion litre thermal heat stores are possibly a good fit for city scale district heating and cooling systems. Such technologies can be deployed in large industrial buildings such as food factories needing lots of hot water and cooling, and store energy cost effectively for weeks.