From Guest Blogger Tom Grant: Reducing Maintenance Costs — Shell and Tube Heat Exchangers to the Rescue

They are popular applications for a good reason, it is an efficient way to conserve energy and this will also help to reduce your maintenance costs as well.

Understanding heat exchangers

To understand how quality heat exchangers can save on maintenance costs, it helps to understand how the process works in basic terms.

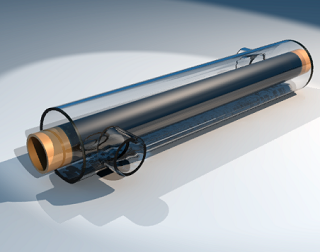

A shell and tube heat exchanger consists of a large pressure vessel which is referred to as the shell, which contains a bundle of tubes inside it. Whilst one fluid flows directly through the tubes inside, another fluid source flows over the tubes, through the shell.

This set of tubes is called a tube bundle and could be made up of several different types of tubing, which work to transfer heat between the two fluids.

Why it works in conserving energy

Heat is transferred from one fluid to the other through the tube walls, either from the outside in or the other way around, whichever is required in the chosen application.

These fluids can either be liquids or gases on either side of the shell tubing, but in order to transfer heat as efficiently as possible, it is always advised that a large heat transfer area is used, which involves numerous tubes. This way you can achieve maximum energy efficiency by making sure that any waste heat is put to use, meaning that conserve energy in the most efficient way.

Heat shrink tubing

The purpose of heat shrink tubing is that it contracts when warmed, meaning that when heat is applied to the heat shrink tubing, the adhesive material contained within the inside of the tube is activated, allowing the adhesive material to become secured to the wire or cable.

This allows the heat shrink tubing to become a single product and therefore more efficient.

Protection and insulation

The purpose of heat shrink tubing is to achieve good insulation but it also provides an excellent level of protection for your wires and cables against elements such as water, oils and other potential environmental hazards that might be present in an industrialized setting.

Polyolefin tubing

There are various types of heat shrinking tubing available but Polyolefin tubing is one of the most popular choices, mainly due to the fact that it is flame retardant and also has good chemical and electrical properties amongst its physical strengths and attributes.

This makes them a sound choice in a potentially volatile environment such as an oil refinery and also in a factory where chemicals are stored or processed.

Easy to work with

Amongst various qualities that a shell and tube heat exchanger possesses, it is popular mainly due to the fact that it is very easy to work with and in most cases, simple to install.

You can order heat shrink tubing in a vast array of different shapes and sizes and there is a great choice of colors too which can help with cable management, but one of the main reasons why companies choose heat shrink tubing, is the opportunity to reduce maintenance costs.